Factors Affecting The Operation Of Distillation Column

Distillation:

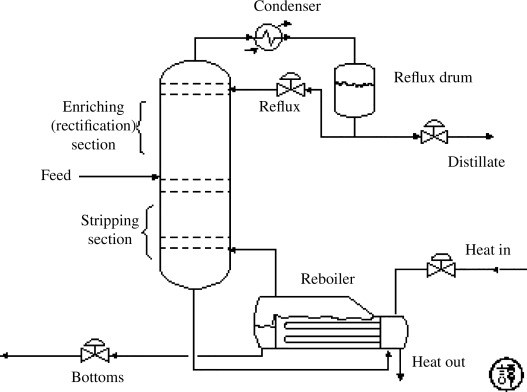

Distillation columns work on the principle of distillation phenomenon at which the separation of liquid and gases take place with the help of their selective boiling point.

Aricle written By : Pallavi Wankhede

Distillation Column:

The Distillation column is one of the most important devices used in the traditional chemical industry like oil and gas. A Distillation column is tall in a structure having trays inside of it. It consists of flammable and combustible fluids. It is also a hazardous process due to its high temperature-pressure conditions.

Problems that usually occur in Distillation Column:

There is a number of a problem or issues that might occur in the distillation column. Usually, they are classified into four types: Problems that occur in Fluid transfer, in Hardware, in Flow condition and problems during any Operation Related.

1. Fluid Related issue:

It includes:

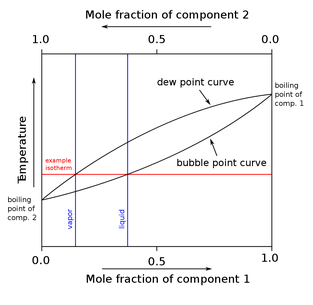

- Close Boiling Liquids due to low relative volatility of the components. It will make the separation of the components difficult.

- Low boiling point liquids due to pressure conditions.

- Azeotropic Mixtures,

- Foaming Types Liquids (Tray Spacing): it occurs when there is an expansion of liquid due to vapor or liquid passage. It might occur due to not proper tray spacing.

- Scaling/ Fouling of Liquids might occur due to not proper cleaning and maintenance.

- Heat Sensitive Liquids (Low temperature)

2. Hardware Related Issues:

It includes:

- Tray column issues might occur due to any false in type and the components of trays used.

- If the installation is not properly done, there is a chance of creating issues in Packed Column where it will affect different types of packing, Components of Packed Column.

3. Flow Related Issue:

It includes:

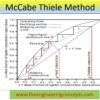

- Flooding is an excessive accumulation of liquid inside the column. It usually occurs due to increased pressure drop across trays where the liquid level in the downcomer increases and reaches the tray above.

- Priming is a process where foam height on the plate reaches the next plate which might reduce the separation efficiency.

- Dumping or Excessive Weeping occurs due to low vapor flow rate. Excessive weeping leads to dumping.

- Entrainment is a process of liquid carried by the vapor up to the tray above due to high vapor flow rates. In this process, the liquid in Vapor Entrainment causes due to a number of contact stages shortfall. Where Vapor in Liquid Entrainment occurs due to occlusion (to close up or block off) in the liquid.

4. Operation Related Issues:

It includes:

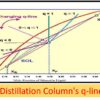

- Feed Conditions includes cold/wet Feed, Saturated Liquid Feed, Partially Vaporized Feed, Saturated Vapor, and Superheated Vapor.

- Reflux Conditions at Minimum, Maximum or Optimum.

- Draw Point Conditions At Top, Bottom, and Intermediate.

Troubleshooting in Distillation Column:

For troubleshooting in the distillation column, it is necessary to study the feed conditions, reflux conditions, internal liquid and other fluid flow conditions, packings in the column, how the installation is done and weather conditions properly.

Content Source:

Lees’ Loss Prevention in the Process Industries (Fourth Edition); Process Plant Layout (Second Edition);

Image Source: http://www.refinerlink.com/; ScienceDirect; Quora; MDPI