What is a Control Loop ?

Understanding a Control Loop : Heat Exchanger Control Loop Example

Source Credits : trerice.com

Control Loop : A controller prime objective is to maintain the measured process variable (PV) at set point (SP) in spite of unmeasured disturbances (D). The major components of a control framework incorporate a sensor, a controller and a final control element. A control loop is a process management system designed to maintain a process variable at a desired set point. Each step in the loop works in conjunction with the others to manage the system. Once the set point has been established, the control loop operates using a four-step process.

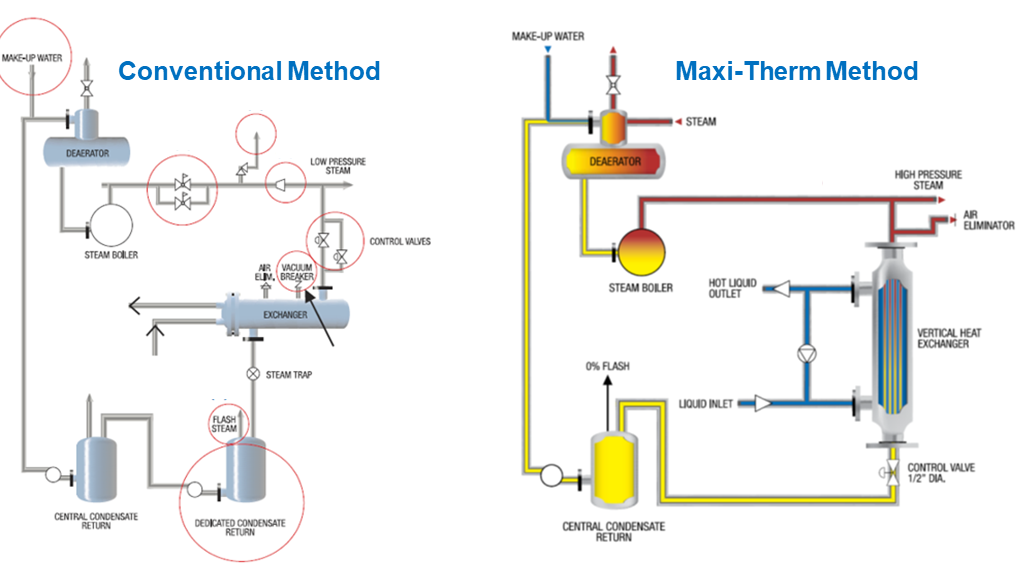

One of the more common projects is to heat water (or some other liquid) from a random cold temperature to a desired working temperature.

Image Credits : watsonmcdaniel.com

The Control Loop Steps :

- Sense : The sensor takes / sense a reading of the process variable or a related measurement by the means of thermocouple or RTD transmitter.

- Compare : The controller receives the signal from the sensor and then forwards it to instrumentation, to remote terminal units (RTU). Evaluate the measurement of the current condition against the set point using an electronic PID controller.

- Respond : Reacts to any error that may exist between the measured temperature value and the temperature set point by generating a corrective pneumatic signal.

- Affect : Actuate the control valve that will produce a change in the process variable to accquire the desired set point

The loop continually cycles through the steps, affecting the process variable (water temperature) in order to maintain the desired temperature set point.

Principle :

An electronic sensor (thermocouple, thermistor, RTD or transmitter) is installed at the measurement location which continuously sends an input signal to the controller. At a fixed intervals, the controller compares the output signal to a defined set point. If the output signal ( which is the input signal for the controller) deviates from the set point, the controller sends a corrective electric output signal to the control element. This electric signal must be converted to a pneumatic signal with the help of transduer and this pneumatic signal is getteing used by an air operated valve. Using a I/P Transducer, which converts a 4 to 20 mA electric signal to a 3 to 15 PSI air signal and sends the respective air supply to the Control Valve Positioner. The valve positioner adjusts the control valve stem position and regulates the flow through the control valve, accordingly the temperature controls. This loop repeats until controller achieves the desired setpoint.

More Articles:

Refrences