Design of Packed Columns

Design of Packed Columns

- A packed column is a hollow tube, pipe, or other vessel that is filled with a packing material.

- Packed columns are used for distillation, gas absorption and liquid-liquid extraction.

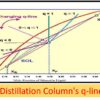

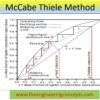

- The gas-liquid contact in a packed column is continuous (or say Rate wise approach ), not stage-wise, as in a plate column.

- The liquid flows down in the column over a packing surface and the vapor (or the gas) moves counter-currently, up the column.

- The packing can be randomly filled with small objects like Raschig rings or else it can be a specifically designed structured packing.

Types of Packing Materials

- Packed beds may also contain catalyst particles or adsorbents such as zeolite pellets, granular activated carbon.

- Packed column utilize packing to contact between the phases (liquid-vapor) on the surface.

- Packed column performs well at low pressure, low liquidand vapor loadingthat make packed column have the most efficient in these terms.

- At high flow parameters the capacity and efficiency can significantly reduce, also in heavy fouling applications and corrosive condition.

- Packed column has less pressure drop than tray column and it reduce foaming since generates thin films instead of fine droplets for mass and heat transfer.

- Packed column is divided by Random, Structured and Grid Packed Columns.

Lets See More About Packed Column by Below Mentioned Slides :

[smartslider3 slider=16]

SourceArticle : Wikipedia ; SlideShare

ImageSource : SlideShare; firthengineering

Also Read:

Venturi Flow Meter

Pitot Tube

Coriolis Mass Flow Meter

Design of Centrifugal Pump

Valve & Its Types

Cavitation

Piping and Instrumentation Diagram – P&ID

Keep visiting More PPT is going to upload continuously on Daily Basis.

Thanks !!