Desuperheater

Aricle written By : Pallavi Wankhede

Desuperheater is very crucial equipment used in the thermal management of industries like refineries, power plants, fertilizers, pulp and paper plants, petrochemicals, etc. Most of these industries work in a higher temperature environment. When steam is saturated and superheated, it is more efficient while performing industrial heat transfer operations.

It is also used in domestic as well as commercial air conditioning and refrigeration systems.

Types of Desuperheater :

There are four types of desuperheaters based on the configurations.

- Indirect contact type: In such type of desuperheaters, the medium used for cooling superheated steam, does not come in direct contact with superheated steam. The medium used for cooling is a liquid or gas instead of surrounding environment. These types of desuperheaters are shell and tube heat exchangers.

- Direct contact type: the medium used for cooling comes in direct contact with the superheated steam. In such type, the medium and superheated steam is the same fluid, occurred in liquid state. Such types are steam desuperheaters and used water as a fluid.

- Integral type: In such type, desuperheater is in-built with actuator. Thus, there is no need to separate the spray water valve.

- Non-integral type: In such type, desuperheater and water valve are separate units.

Also Read : Heat Exchanger Design

Also Read : What is Pump Head and Shut-off Head ?

Instead of all these configurations, manufacturers are offering a broad choice for desuperheaters. These are: Venturi, Annular Venturi, Annular Venturi Orifice, Attemperator, Steam Ejector, Atomizing, Mechanical Atomizing Dump, and Surface Absorption Desuperheater, etc.

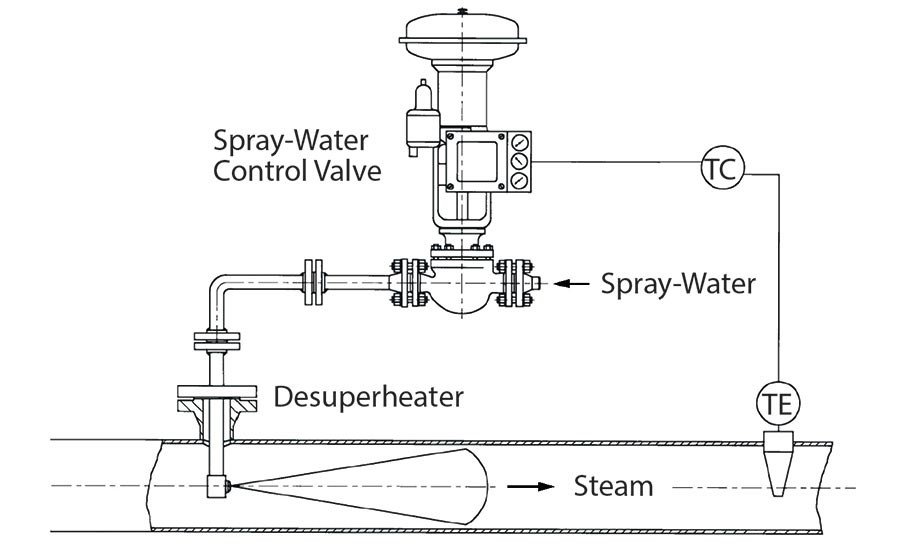

Working Principle:

- As the name desuperheater suggests itself it is a device that works opposite of super-heater.

- Desuperheater works on a quite simple principle. The main function of desuperheater is to minimize the temperature of superheated steam and other vapors (having temperatures above its boiling point, e.g. Water has a boiling point of 100 0C, also called as its saturation temperature, if you start boiling water after 100 0C, it will convert into superheated steam. For more information about steam classification, please refer the steam table).

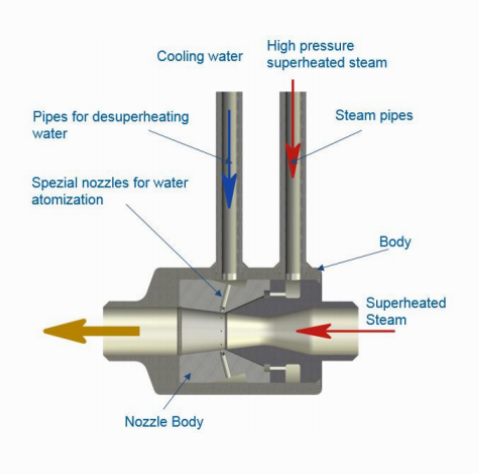

- The liquid used while reducing the temperature of superheated steam to a controlled condition is usually water. The water droplets are directly injected into the flow of superheated steam through a spray nozzle.

- Once the superheated steam gets cooled, the water injected into the flow is then evaporated.

Figure 2: Desuperheater

Selection and the efficiency:

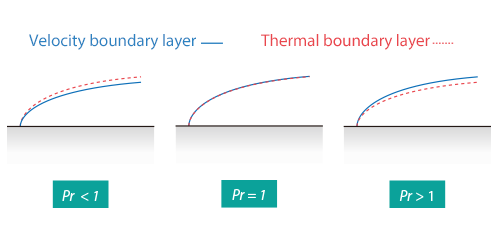

- Desuperheaters are installed for the effective performance of heat transfer between steam or vapor (saturated, superheated) and water.

- The orientation of desuperheaters might affect the speed of vaporization while spraying droplets into superheated steam. Horizontal installations are most commonly used in the industry. While in vertical installations, the flow up position can perform slightly better due to the positive effect of gravity. On the other hand, the flow down position performs less efficiently due to the negative effect of gravity which also reduces residence time.

- In order to achieve the higher efficiency of desuperheaters with respect to its design, problems like long startup and shutdown time, the wear of downstream piping and equipment, reduced process efficiency should be avoided.

- While specifying the desuperheaters, it is advisable to consult with the manufacturers as per process requirements. As there are multiple models of desuperheaters available in the market.

Content Source: MANIKS ; Process Heating; Virginia Heat Transfer

Image Source: Process Heating; AVK Flow Control; Electrical Instrumentation CAD

Video Source : Spirax Sarco Italy