Types of Pressure Vessel Head

A pressure vessel is a closed container (either cylindrical or spherical) which is used mainly to store or hold the processing gases, liquids ( water or some fluids) at a designed internal or external pressure at various operating temperature.

According to ASME Section VIII, Div 1 pressure vessel is defined as : “ Pressure Vessels are containers for the containment of pressure either external or internal. The pressure may be obtained from an external source, or by the application of heat from a direct or indirect source, or any combination thereof.”

A Common or Day to Day example of pressure vessel is : Pressure Cooker

Pressure Vessel Head or End Closure of vessel

The closing end (either one side or both side) of the pressure vessel is termed as Head or End closure or Dished Head. Somewhere it also works/considered as manhole of the vessel.

” The portion above the shell is known as Top-Dished Head and the portion below the shell is considered as Bottom Dished Head”

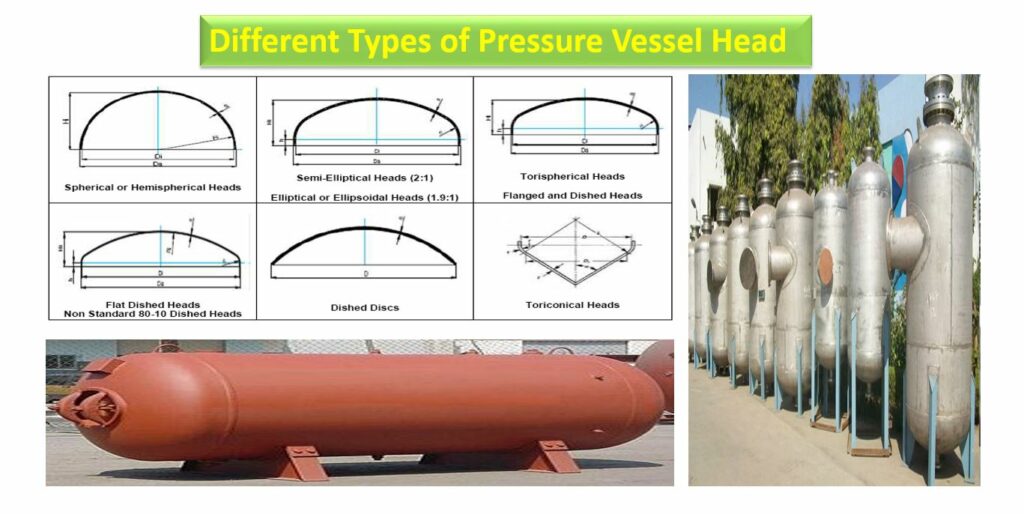

Different Types of End closure are as below:

- Flat Heads

- Formed Head

The heads are attached with the vessel/shell either by welding or by means of nut & bolt.

Flat Head :

- This type of head is mainly used for small diameter vessels.

- Very Simple in construction.

- They are used for covering manhole many-where

- Used in low pressure vessel frequently.

The thickness of the Head is calculated By :

where

t=thickness of head

di= inner diameter of vessel shell

Pi = design pressure, N/mm2

σ = allowable tensile stress, N/mm2

C = corrosion allowance

Formed Head

Commonly used head used in pressure vessel operating under various operating temperature and pressure.

Different types of formed head are :

- Plain formed head

- Torispherical Dished Head

- Semi-Elliptical Dished Head

- Hemispherical Head

- Conical head

Plain Formed Head

- This type of plain head or plain formed head is used for horizontal cylindrical storage vessel /shell operating under atmospheric pressure.

- This is also used as the bottom end of vertical cylindrical vessel ; resting on concrete slabs and do not have diameter in excess of 7 meters.

- The thickness of the plain formed head is given by :

where

th=thickness of head , mm

di= inner diameter of vessel shell

Pi = design pressure, N/mm2

σ = allowable tensile stress, N/mm2

C = corrosion allowance

ric = inner corner radius, mm ≥ ?. 1di

Sf = straight flange length, mm = 3 th or 20 which ever is greater

Read Also :

Pressure Vessel

TYPE OF PRESSURE VESSEL

The 3 Most Common Types of Pressure Vessels

Torispherical Head

- The torispherical dished heads are used for vertical or horizontal pressure vessel or horizontal pressure vessel in the pressure range from 0.1 N/mm2 or 1.5 N/mm2

- These type of heads are shaped by using two radii : the dish radius or crown radius (Rc) & inner corner radius or knuckle radius (ric)

- Applicable for Low Thick Vessel

- The thickness of the torispherical dished head is given by,

Semi-Elliptical/Ellipsoidal Head

- The Semi-elliptical dished heads are used for pressure vessels above 1.5 N/mm2 pressure.

- The ratio of the major axis to the minor axis is generally taken as 2.

- The thickness of the semi-elliptical dished head is given by,

- Here S f = 3 th or 20 mm, Whichever is greater.

Hemispherical Head

- As the name suggests, the profile of this type of head is hemisphere.

- Have throughout constant radius

- Considered as strongest among all Formed Heads / Dished Heads.

- Used in high pressure vessels where the vessel is thickness is also high.

- Not applicable where small space is required.

- The thickness of the hemi-spherical dished head is given by,

- S f = 3 th or 20 mm, Whichever is greater

Conical Head

- Widely used as bottom heads.

- It facilitate the removal or draining of the material.

- Not used in the Dished Head of pressure vessel because this worked under lower pressure.

- This is of cone shape where the semicore angle is generally taken as 300.

- The thickness of the Conical dished head is given by,

- Where S f = 3 th or 20 mm, Whichever is greater

ImageSource : marineoutfittings.com; pritaminternational.com; Slawinski – dished ends manufacturer ; Zeyon, Inc. ;