Feedforward Vs Feedback Control

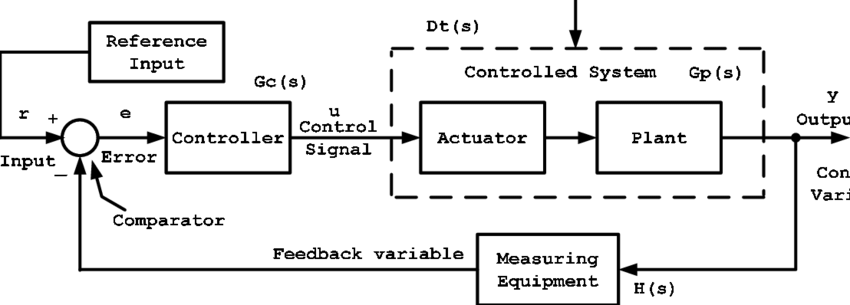

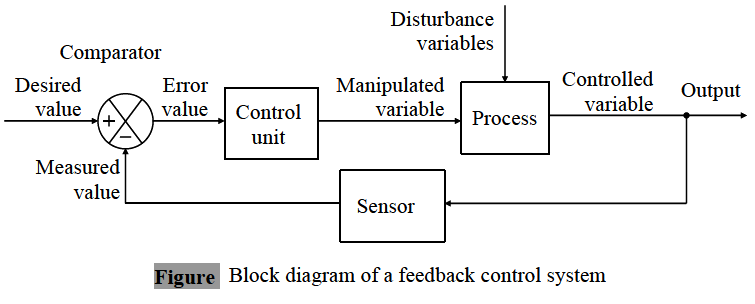

Feedback Control

Feedback Control is considered as an important technique widely used in around all process industries.

Its main advantages are as follows.

- As the controlled variable/control objective deviates from the set point, corrective action taken very instant; irrespective of source and type of disturbances.

- Feedback is reactive in nature.

- Here, Corrective action taken by the controller occurs after the disturbance observed in the output.

- Minimal knowledge requires about the processed to be controlled, helpful in control system design.

- The ubiquitous PID controller is both versatile and robust. If process conditions change, retuning the controller usually produces satisfactory control.

However, feedback control also has certain inherent disadvantages:

- No corrective action is taken until after a deviation in the controlled variable occurs. Thus, perfect control, where the

controlled variable does not deviate from the set point during disturbance or set-point changes, is theoretically impossible. - Feedback control does not provide predictive control action to compensate for the effects of known or measurable

disturbances. - It may not be satisfactory for processes with large time constants and/or long time delays. If large and frequent

disturbances occur, the process may operate continuously in a transient state and never attain the desired steady state. - In some situations, the controlled variable cannot be measured on-line, and, consequently, feedback control is not

feasible.

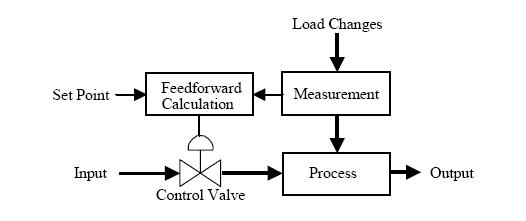

Feedforward Vs Feedback control Images

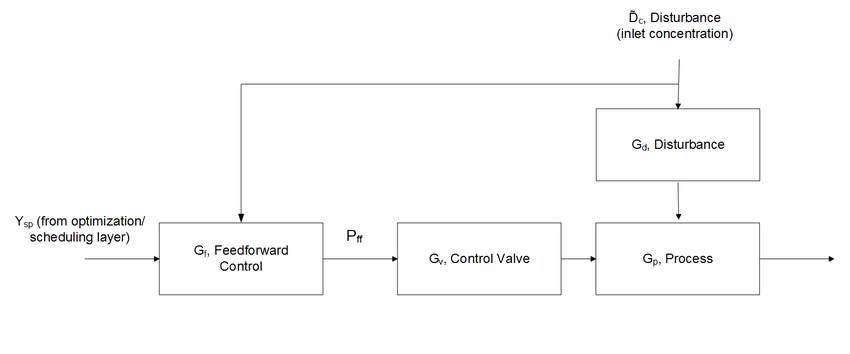

Feedforward control

Feedback control

Let’s talk about Feedforward Control

Feedback control also has certain inherent disadvantages:

- No corrective action is taken until after a deviation in the controlled variable occurs. Thus, perfect control, where the controlled variable does not deviate from the set point during disturbance or set-point changes, is theoretically impossible.

- Corrective action taken before the actual disturbance occurs on the output.

- Feedback control does not provide predictive control action to compensate for the effects of known or measurable disturbances.

- It may not be satisfactory for processes with large time constants and/or long time delays. If large and frequent disturbances occur, the process may operate continuously in a transient state and never attain the desired steady state.

- In some situations, the controlled variable cannot be measured on-line, and, consequently, feedback control is not feasible.

ImageSource : ResearchGate; Instrumentation Forum

ArticleSource : sites.chemengr.ucsb.edu;

Also Read:

Liquid Level Flow Control Loop

Heat Exchanger Temperature Control

Piping and Instrumentation Diagram – P&ID

How to choose betwwen PLC and DCS systems for process industries ?

What is the Difference Between HMI and SCADA?

What is SCADA ? How does SCADA Works?

What is Programmable Logic Controller / PLC ?

What is Distributed Control Systems (DCS) ?