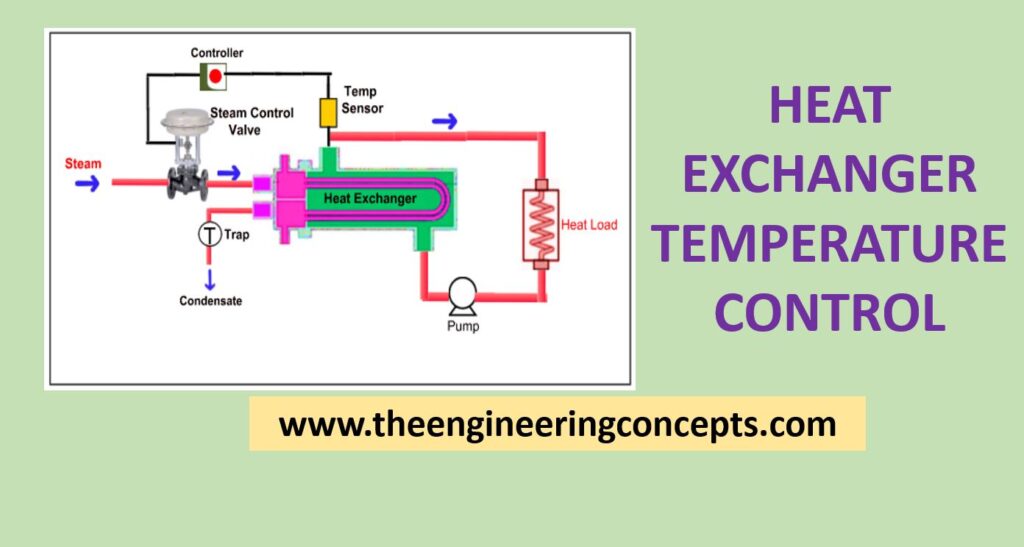

In case of heat exchanger two different fluids ( one having high tempture (hot fluid) & other having low temperature (cold fluid) brings into direct/indirect contact (mainly indirect contact) to achieve a desired / controlled temperature. Here our purpose is to attain a desired temperature of process fluid / cold fluid. In this context indirectly contacting this cold fluid with the hot fluid / steam to attain a specific temperature of cold fluid.

Control Objective :

In order to develop a complete control strategy for this control loop, it is very important to identify the process variables first or one have to identify first what is controlled variables, what is manipulated variables and what falls under disturbance variables list.

Here the outlet temperature of process fluid (Tcold, outlet) is considered as controlled variable, which is your desired output.

Manipulated Variable : Steam Flow Rate (Inlet flow rate of hot fluid) ; as more steam passes more heat transfers takes place and vice-versa. Hence, steam flow is achieved by throttling a modulating valve installed on the steam inlet side

Major disturbances : Those parameters which affects the process fluid outlet temperature / desired temperature:

- Changes in process fluid / cold fluid flow rate.

- Changes in steam/hot fluid inlet temperature

- Changes in steam pressure, causing a change in steam flow rate.

Control Action :

- In this loop proportional-integral-derivative (PID)-based feed forwards scheme, should be placed to take a corrective action when a disturbance ocurrs.

- In case of feed forward, what ever the disturbances ocurrs that gets accounted ( Here by means of temperature transmitter measures the outlet temperature, including disturbance effects) and a comparison done between set point and measured output, whatever the error is their—–on that controller takes necessary action and accordingly gives command to final control element (Control Valve) for how much, % open / %close. In this way steam flow rate increases/decreases and thus the outlet temperature of process fluid ( cold fluid) is the desired temperature.

In the feedback control scheme, the process variable, T1Out, is measured and applied to a proportional-integral-derivative (PID)-based feedback temperature controller (fbTC), which compares the process variable with the desired temperature setpoint and in turn calculates and generates the control action required to open or close the steam control valve .

The most important advantage of the feedforward control scheme is that regardless of the disturbance source, the controller will take corrective action. Employing feedback control requires very little knowledge of the process. Therefore, a process model is not necessary to set up and tune the feedback scheme, although it would be an advantage.

The major disadvantage of feedback control is its incapability to respond to disturbances—even major ones—until the controlled variable is already affected. Also, if too many disturbances occur with significant magnitude, they can create unrecoverable process instability.

Thus one can say feedforward controller quickly and directly compensate on the effect of a disturbance.

To implement feedforward control, an understanding of the process model and the direct relationship between disturbances and the process variables is necessary. For heat exchangers, a derivation from the steady-state model will lead to the following equation, which determines the amount of steam flow required:

F2sp = F1 × (T1OUT sp – T1IN) × (Cp/ΔH)

Where:

- F2sp = steam flow rate calculated set point to be applied to fbFC

- F1 = process fluid flow rate measured disturbance

- T1OUTsp = process fluid temperature set point at the heat exchanger outlet

- T1IN = process fluid inlet temperature measured disturbance

- Cp = process fluid specific heat (known)

- ΔH = latent heat of vaporization for steam (known).

Reference : Control Engineering;

ImageSource : Control Engineering; the control blog

Also Read:

Piping and Instrumentation Diagram – P&ID

How to choose betwwen PLC and DCS systems for process industries ?

Cement Manufacturing Process

Vinyl Chloride from Ethylene

Cooling Tower

Psychrometric Chart

What is Boiler ?

Venturi Flow Meter

Pitot Tube

Coriolis Mass Flow Meter

RECIPROCATING PUMP

Design of Centrifugal Pump

Valve & Its Types

Cavitation

P&ID Symbols and Notation

What is the Difference Between HMI and SCADA?

What is SCADA ? How does SCADA Works?