What is P&ID?

- A piping and instrumentation diagram (P&ID) is a drawing in the process industry.

- A P&ID shows all piping, including the “physical sequence of branches, reducers, valves, equipment, instrumentation and control interlocks.”.

- P&ID is the diagram which shows the interconnection of process equipment and the instrumentation used to control the process.

The following list outlines the items that typically are found in a piping and instrumentation diagram:

- Instrumentation and designations

- Mechanical equipment with names and numbers

- All valves and their identifications

- Process piping, sizes, and identification

- Vents, drains, special fittings, sampling lines, reducers, increasers, and swaggers

- Permanent start-up and flush lines

- Flow directions

- Interconnections references

- Control inputs and outputs, interlocks

- Interfaces for class changes

- Computer control system

- Identification of components and subsystems delivered by the process

The uses of P&ID are as follows

- Piping and instrumentation diagram is the basis for developing the control systems in the chemical process.

- It helps in Equipment design and Piping design and also serves to estimate the capital cost.

- Hazard and Operability (HAZOP) Study is performed during the design stage with the help of P&I diagram.

- It will assist in preparing Commissioning procedure, Pre-Startup Safety Review, Standard Operating Procedures for Startup, Normal operation and Shutdown.

- It also assists in preparing Plant Operating manual

- Control narrative and Interlock narratives will be prepared by having P&ID as the basis.

- It will help to prepare the Instrument Index and other will serve as a reference for creating other datasheets.

- It acts as a beacon for newbie process engineer in a Chemical Industry.

- P& ID also helps in Incident investigations to find out What Went Wrong through root cause analysis.

- It helps in evolving maintenance procedures of equipment. It helps to visualize the interconnecting systems with the equipment and planning for proper isolation can be done.

What is the difference between P&ID and PFD?

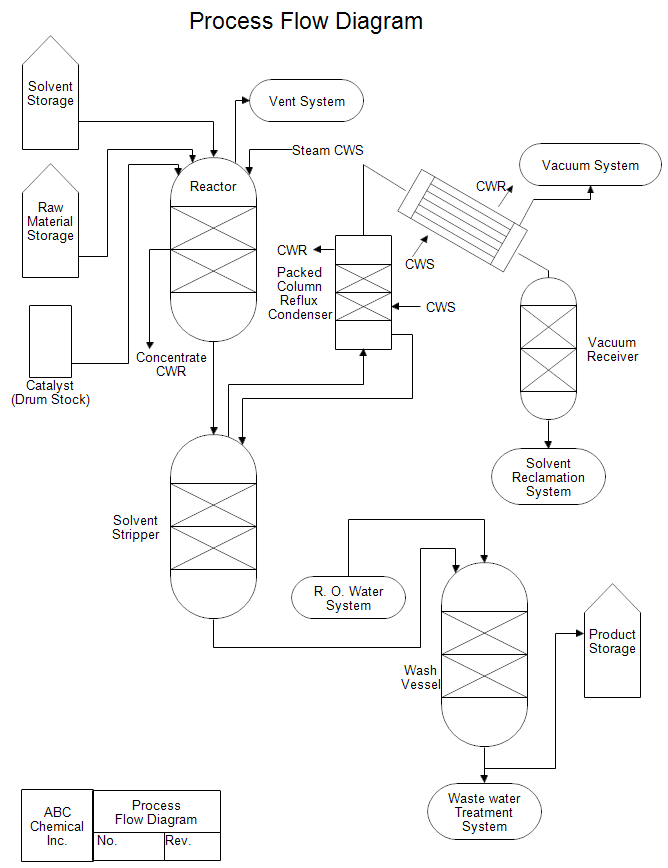

Process flow diagrams (PFDs) are used in chemical and process engineering. These diagrams show the flow of chemicals and the equipment involved in the process. Generally, a Process Flow Diagram shows only the major equipment and doesn’t show details. PFDs are used for visitor information and new employee training.

Process Flow Diagram (PFD) is used for indicating the general flow of process and equipment. It helps to visualize the overall process of the in a chemical plant.

PFD will contain main process piping, Main equipment number, Equipment Name, Flow directions, Major bypass lines, Critical Control Valves that affects the process, Stream Number, Stream Designation, Process parameters like operating temperature, operating pressure, flow rate, Composition and heat duty of heat transfer equipment.

PFD will not contain Piping size and classification, Process control Instrumentation details like Transmitters, Control valves, Design Temperature and Pressure, Material of Construction of Equipment and piping, Mechanical Valves for isolation, Vents and Drains, Relief valves & Safety Valves.

Example of simplified process flow diagram

Where as ,

A Process and Instrument Drawing includes more details than a PFD. It includes major and minor flows, control loops and instrumentation. P&ID is sometimes referred to as a Piping and Instrumentation Drawing. These diagrams are also called flowsheets. P&IDs are used by process technicians and instrument and electrical, mechanical, safety, and engineering personnel.

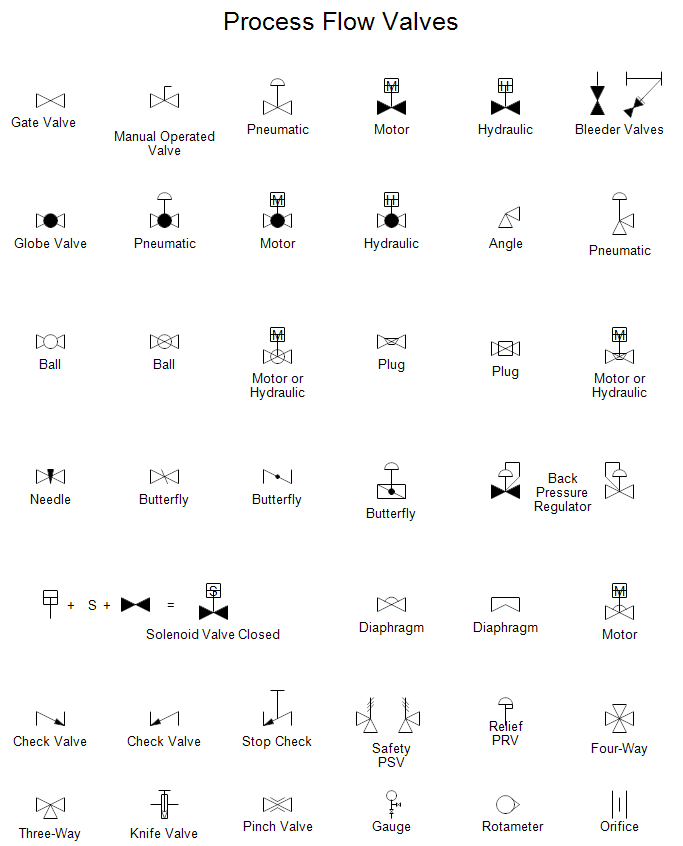

In both diagrams arrows show the flow of material and symbols show tanks, valves, and other equipment. The symbols used vary somewhat from organization to organization. So you may see several different symbols that all represent a motor.

P&ID will contain Equipment number, Equipment Name, Process and Utility piping, Piping size and classification, Instrumentation details like Transmitters, Control valves with their numbers, Control input and output, Annunciation input, SIS input, solenoid valves, On-off valves, Motorised valves, Relief valves, All Mechanical valves Miscellaneous items like strainers, Vents, drains, Silencers, standpipes etc, Vendor items and interfaces, Equipment design pressure, Temperature and Material of Construction, Free draining requirements etc. P&ID will also have general notes that will assist during Detailed Engineering, Erection and Commissioning phase. Though it is not an exhaustive list, Our P&ID Check list in the trailing part of this post will help you to explore in detail about Piping and Instrumentation Diagrams.

P&ID will not contain Operating parameters, Equipment elevation details, Elbows, MTO, etc. It is not drawn to scale and hence geometric accuracy can not be expected out of P&ID.

P&ID Symbols

Also Reads : Valve Symbols for P&IDs

The instrumentation symbols used in P&ID are as per ISA-S5.1 standard – Instrumentation Symbols and Identification. For Symbols of chemical apparatus and equipment normally ISO, JIS, DIN or PIP standards are followed.

An Example Diagram from Butterfly Valve

What are the Softwares available to make P&ID?

There is some renowned P&ID software available that can be used online and offline. It saves time in creating a P&ID with the help of simple user-friendly tools available in them. Some of them are,

Autocad is one of the worlds leading design and drafting software used by many of the Chemical Process Design companies for preparing P&ID. 2D and 3D design drawings also can be made out of it.

MS-Visio is very useful offline software for Chemical Engineers to prepare PFD, P& ID and other diagrams in a simple way by just dragging and dropping the symbols.

Lucidchart is an online software for preparing P&I diagrams in a fast manner. Anyone can make the drawing with a drag and drop option. This simple and efficient software also has the functionality to import and export from MS- Visio.

Procad PROCAD P&ID is powered by AutoCAD®, the most popular CAD software. It generates files in DWG format for maximum portability of design data.

P&ID Review Checklist

Chemical Engineer must review the P&ID before finalizing them for implementation.

What is P&ID?.

P&ID is the diagram which shows the interconnection of process equipment and the instrumentation used to control the process.