Types of pressure gauge based on the working principle

Pressure is defined as force per unit surface area that a fluid (Liqud or Gases) exerts on its surroundings. Pressure, P, is a function of force, F, and area, A:

P = F/A

The SI unit for pressure is the pascal (N/m2), but other common units of pressure include pounds per square inch (psi), atmospheres (atm), bars, inches of mercury (in. Hg), millimeters of mercury (mm Hg), and torr.

Pressure gauges are devices used to measure pressure, all pressure gauges have their own sensing element, which senses the value of the measured quantity.

Here in this Artice we see the three different types of pressure gauge frequently available in industries are :

-

Diaphragm

-

Bellow

-

Bourdon tube

- Other Types : Strain gauge , Piezoelectric ( will see in next Article )

1) Diaphragm Pressure Gaguge

A diaphragm pressure gauge is a device that uses a diaphragm with a known pressure to measure pressure in a fluid. The diaphragm is an elastic membrane that elongates when pressure is applied to it. The diaphragm is a single sheet which elongate, Joining two diaphragm to form a capsule.

Two capsules joining to form a stacked diaphragm. Adding more capsules to the diaphragm increases the sensitivity of the gauge.

When pressure is applied to the diaphragm, it flexes. The movement is transmitted by a link that connects to the pointer. The pointer moves to indicate the amount of pressure applied to the diaphragm. The diaphragm stays at the original position until a pressure is applied to it.

Diaphragm pressure gauges are considered as specialists in the process industries. They come into play when Bourdon tube pressure gauges reach the limits of their performance. One of the advantages of diaphragm pressure gauges is the measurement of low pressures.

Applications for diaphragm pressure gauges:

- Suitable in corrosive environments for gaseous, liquid or highly viscous media.

- With liquid filled case for applications with high dynamic pressure pulsations or vibration.

- Process industry: chemical/petrochemical, power stations, environmental technology, mechanical engineering and plant construction.

2) Bellow Gauge

The below is another type of stacked diaphragm. The stacked diaphragm is made of several sheets, while the bellow is made of single sheet. Bellows gauges contain an elastic element that radially expands and contracts to respond to pressure changes. The applied pressure makes the bellows expand. The expansion causes the bellows to get longer. When pressure is removed, the bellows get shorter. The internal bellows is connected to a pointing device so that subtle movements due to pressure fluctuations are indicated on pressure calibrated scale on the dial. The pointer indicates the pressure applied to the bellows.

Bellows gauges excel in low pressure applications and have the accuracy and sensitivity for precise measurement. Additionally, bellows gauges are rugged and reliable with low hysteresis and creep. Like Bourdon tubes, bellows gauges are sensitive to vibration and shock.

Image Bellow Gauge

Source : http://users.telenet.be/instrumentatie/index.html

For selecting a specific material for an elastic member of bellows, following of the parameters to be checked :

- Range of pressure

- Hysteresis

- Fatigue on dynamic operation

- Corrosion

- Fabrication ease

- Sensitivity to fluctuating pressures

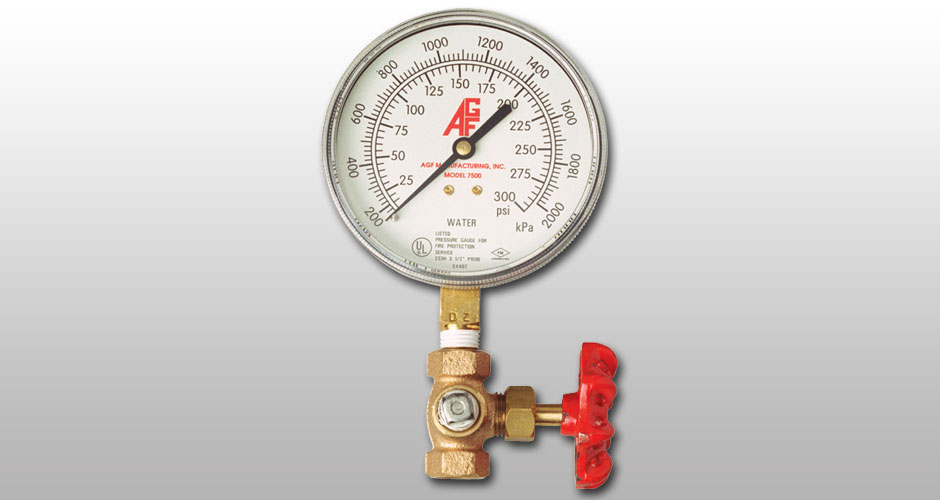

3) Bourdon Gauge

The bourdon tube is the ‘C’ shaped tube shown in the above figure. When a pressure is applied to the C tube which is oval in shape, the tube stretches outwards and try to acquire circular cross sectional shape

Bourdon Tube Working Principal Image

The tube end is attached to a pointer using a link. The link-gear system makes the pointer moves along the scale. The circular motion of the pinion gear drives the position of the pointer to indicate the amount of pressure applied to the Bourdon tube.

Bourdon Tube Pressure Gauge

Bourdon tube pressure gauges work very well for most applications, particularly those involving medium to very high pressures. They are simple in construction, which keeps them inexpensive and easy to use. Bourdon tubes also offer superior linearity and can be accurate up to ±0.1% making them suitable for precision measurements.

Read Also :

-

Pitot Tube Working Principle

-

Venturi Flow Meter

-

Design of Centrifugal Pump

-

Valve & Its Types

-

Cavitation

-

Piping and Instrumentation Diagram – P&ID