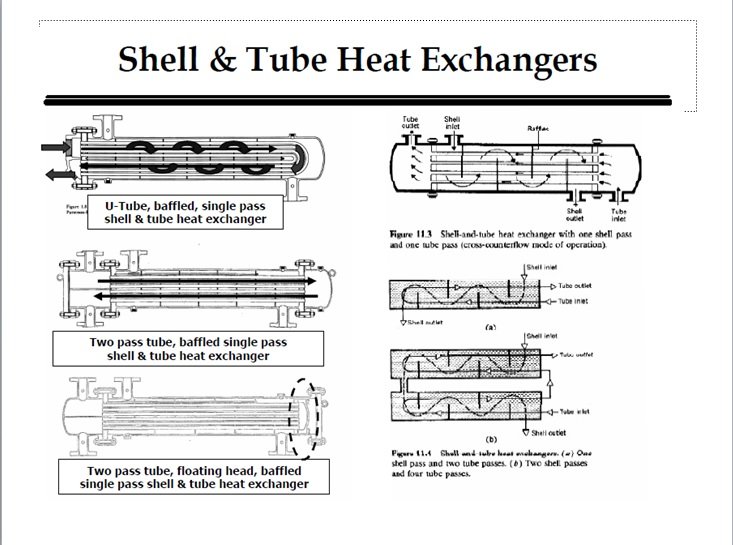

Shell & Tube Heat Exchanger

Layouts

Shell and tube (a.k.a. multipass) heat exchangers are the most common industrial application for liquid/liquid heat exchange.

Inside the shell, baffles (dividers) are installed to direct the flow around the tubes, increase velocity, and promote crossflow. They also help support the tubes. The baffle cut is the ratio of the baffle window height to the shell diameter. Typically, baffle cut is about 20 percent. It effects both heat transfer and pressure drop. Designers also need to specify the baffle spacing; maximum spacing depends on how much support the tubes need.

A pass is when liquid flows all the way across from one end to the other of the exchanger. We will count shell passes and tube passes. An exchanger with one shell pass and two tube passes is a 1-2 exchanger (shown in the figure). Almost always, the tube passes will be in multiples of two (1-2, 1-4, 2-4, etc.), since odd numbers of tube passes have more complicated mechanical stresses, etc. An exception: 1-1 exchangers are sometimes used for vaporizers and condensers.

1 Response

[…] Also Read : Shell and Tube Heat Exchanger Design […]