Thermosyphon Reboiler

Thermosyphon Reboiler

A reboiler is nothing but a heat exchanger. It plays a vital role in the transfer of heat through fluid during any chemical process. In distillation column, it is used to generate the vapor which is supplied to the bottom tray of the column.

Aricle written By : Pallavi Wankhede

- Thermosyphon reboiler is one of the types of reboiler. This type of reboiler is mostly shell and tube exchanger. The boiling of the fluid takes place either on the shell side or tube side of the exchanger.

- The thermosyphon reboiler does not require the pumping of the liquid from the column bottom to the reboiler. It takes place through natural circulation.

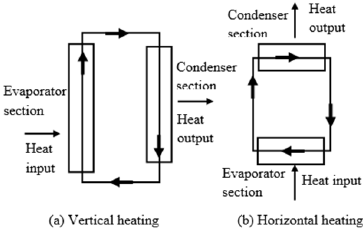

- The thermosyphon reboiler type is classified according to its orientation and type of circulation used. They are Vertical and horizontal type.

Also Read : Heat Exchanger Design

Horizontal Thermosyphon Reboiler:

- Horizontal thermosyphon reboilers are the most commonly used reboilers in the refining industry.

- It has shell side as process side and the tube side as the heating medium.

- The boiling will take place on the shell side of the reboiler. The recirculation takes place at the base of the distillation column.

- In a horizontal thermosyphon reboiler, the liquid from the column will pass through a cross-flow over a tube bundle and the liquid-vapor mixture will return to the column.

- The heating fluid will remain inside the tube.

- The horizontal thermosyphon reboiler will help to conserve natural circulation by allowing lower headroom as compared to the vertical thermosyphon reboiler.

- Apart from these, this reboiler type has more uncertainties about the cross-flow in heat transfer rates and the fouling.

Figure 2: Horizontal Thermosyphon Reboiler

Vertical Thermosyphon Reboiler:

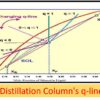

- In the vertical thermosyphon reboiler, the liquid will pass from the bottom of the column to the reboiler. During the transfer of liquid, evaporation takes place inside the tube. The two-phase mixture, liquid and vapor discharged back into the column where the liquid settles back to the liquid pool and the vapor will go up in the column.

- The liquid circulation occurs due to the density difference in the liquid-vapor mixture (two phases).

- The heating fluid (condensing steam) is on the outside of the tubes.

- On the other hand, this reboiler is less susceptible to fouling problems.

- It has a higher heat transfer coefficient. However, this reboiler type requires additional height to mount.

Working Principle:

- Thermosyphon reboiler works on the principle of thermosiphon effect. Thus, it is named as thermosiphon/thermosyphon reboiler.

- Thermosiphon effect is the passive exchange of heat due to natural convection. It is also called thermosiphoning. It provides a motive force due to natural convection.

- The thermosyphon reboiler uses this motive force to create a cyclic flow from high heat to low heat and low heat to high heat.

- Thermosiphoning gives the circulation of liquids and volatile gases in heating and cooling.

Also Read : Baffles (Heat Transfer)

Selection and efficiency:

- Selection of Reboiler design is completely dependent on the service required in the unit. It is the most critical part of the selection procedure of the reboiler.

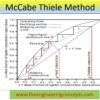

- For effective distillation, proper reboiler operation is required.

- Thermosiphon reboiler boils the liquid from the bottom section of the distillation column. This boiling is useful for better separation in the distillation column. Boiling will partially or completely vaporize the steam (formed due to boiling of bottom liquid). Once the boiling is done, the heat generated due to steam will be supplied to condenser at the top of the distillation column and it is removed afterward.

- It gives a simple and compact piping arrangement. Also, it provides excellent thermal performance in the distillation column.

- It is advisable to use an iterative design procedure for reboilers due to the interrelation between terms like circulation rate, heat transfer rate and pressure drop. If one of these terms changes, it might affect the other two terms.

- The circulation in the reboiler is achieved by the difference between the hydraulic head of the liquid in the distillation column and the head of the two phase mixture in the reboiler.

- On the other hand, it is not suitable for viscous and solid bearing fluids. When it is used in vacuum operation, there might be a need for more heat transfer area.

- The horizontal thermosyphon reboilers are most suited for large duties. Also, its maintenance is easy as tube bundles can be easily withdrawn.

- To provide the hydrostatic head, the distillation column base should be elevated properly to create a thermosiphon effect. It might increase the cost of the column supporting structure. Thus, it is mostly relying on the gravity and respective hydrostatic head to return the condensed or cooled fluid to the heat source.

Content Source: AONG website; PARAMOUNT LIMITED

Image Source: THERMOPEDIA; Vidya-mitra; ResearchGate