Venturi Flow Meter

Basics of Venturi Flow Meter

Venturi meter is a device used to measure the rate of flow and flow rate of fluid through a pipe.

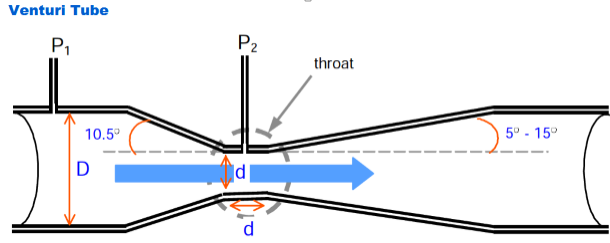

Venturimeter comprises of three main sections

- Converging section

- Throat

- Diverging section

Image Source : http://scharfautomation.com/

Converging section: It is that portion of the venturimeter where the fluid gets converges. Fluids gets accelerated in this section.

Throat: It is the portion that lies in between the converging and diverging part of the venturi. The cross section of the throat is much less than the cross section of the converging and diverging parts. As the fluid enters in the throat, its velocity increases and pressure decreases.

Throat is of smallest area / diameter of the venturi-tube. The restriction diameter should not be less than 0.224 D, and not more than 0.742 D where D is the nominal bore diameter of the pipe. When the fluid flows through it, the pressure at the throat is lower than the upstream pressure (because of increased kinetic energy due to increased velocity, ½ mv2) and the consequent reduction in flow energy.The flow rate is proportional to the pressure difference, P1 P2.

Diverging part: It is the portion of the venturimeter (venturi) where the fluid gets diverges.

The converging section increases/accelerates the fluid which gives maximum velocity and minimum pressure In a brief venturimeter uses the converging section of a pipe to give an increase in the flow velocity and a corresponding pressure drop from which the flow-rate can be deduced. They have been in common use for many years, especially in the water supply industry.

Principle of Venturimeter

The working of venturimeter is based on the principle of Bernoulli’s equation.

Bernoulli’s Statement: It states that for a steady, inviscid ( ideal flow/potential flow), incompressible fluid the total mechanical energy along a stream line is constant. The total mechanical energy consists of pressure energy, kinetic energy and potential energy or datum energy.

Bernoullis Principle

If we also include irrotational flow in our assumption then the total mechanical energy along the flow field is constant.

Mathematically

Here all the energies are taken per unit weight of the fluid.

Venturi Effect Video

Working

The venturimeter is used to measure the rate of flow of a fluid flowing through the pipes. Lets understand how it does this measurement step by step.

- Here we have considered two cross section, first at the inlet and the second one is at the throat. The difference in the pressure heads of these two sections is used to calculate the rate of flow through venturimeter.

- As the water enters at the inlet section i.e. in the converging part it converges and reaches to the throat.

- The throat has the uniform cross section area and least cross section area in the venturimeter. As the water enters in the throat its velocity gets increases and due to increase in the velocity the pressure drops to the minimum.

- Now there is a pressure difference of the fluid at the two sections. At the section 1(i.e. at the inlet) the pressure of the fluid is maximum and the velocity is minimum. And at the section 2 (at the throat) the velocity of the fluid is maximum and the pressure is minimum.

- The pressure difference at the two section can be seen in the manometer attached at both the section.

- This pressure difference is used to calculate the rate flow of a fluid flowing through a pipe.

Venturimeter is connected with a U-shaped tube filled partially with mercury. The venturi meter is connected to a pipe at two points as shown in the fig. 1.

The area of cross sections of pipe at ends where the venturi meter has been connected are A1 and A2respectively. The corresponding velocity of fluid are v1 and v2. Let P1 and P2 are the pressure of fluid at the two ends 1 and 2.

Bernouilli’s equation can be written as,

![]() —————- ( i )

—————- ( i )

After rearranging eq(i) we get

![]()

![]() ——————————– ( ii )

——————————– ( ii )

As per continuity equation

![]()

or, ![]() ——————————– ( iii )

——————————– ( iii )

By replacing ![]() in equ(ii) using eqn (iii)

in equ(ii) using eqn (iii)

——————————– ( iv )

——————————– ( iv )

|

or,  ———————— ( v )

———————— ( v )

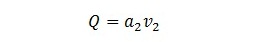

The volume flow rate can be calculated as,

————————– ( vi )

————————– ( vi )

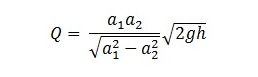

Discharge

Substituting value of v2 in above equation

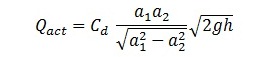

Q is the theoretical discharge under ideal conditions. Actual discharge will be less than the theoretical discharge. The actual discharge is given by the formula

Where Cd is the coefficient of venturimeter and its value is less than 1.

The venturi flow meter should always be used for turbulent flow. Its accuracy for a wide range of instruments is about 0.5%. ideal for use in Heat Ventilation Air Cond. (HVAC) applications, or air to furnaces and boilers and for liquids containing particles and slurries.

What is Venturi effect ?

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after Giovanni Battista Venturi (1746–1822), an Italian physicist.

Venturi Flow Meter Animation

- Pressure recovery for venturi tubes is a better than that of the orifice meter.

- Venturi tubes are appropriate for clean, dirty and viscous liquid and few slurry services as well.

- In venturi tubes, pressure recovery is more compared to other flow measuring devices .

- Essential upstream pipe length of a venturi tube is 5 to 20 diameters.

- A venturi tube can pass 25 to 50% extra flow than that of an orifice plate keeping the same drop in pressure.

- Since, the early cost of a venturi tube is quite high, it is mainly engaged on larger flows and in more complicated or challenging flow applications.

- Unlike orifice plates, venturi tubes are almost insensitive to velocity profile effects and consequently call for less straight pipe run than an orifice.

- Venturi tubes are resistant to corrosion, erosion, and internal scale build up, owing to their contoured nature, pooled with the self- scouring action of the flow through the tube.

- Use of venturi tubes involves a lot of savings in installation and operating and maintenance costs.

- Venturi tube flowmeters are frequently used in applications involving higher TurnDown Rates or lower pressure drops, particularly in areas where orifice plates fails to perform.

Advantages of Venturi meter:

- They can handle large flow volumes at low pressure drops.

- Venturi tube flowmeters involve no moving parts.

- They can be mounted in large diameter pipes via flanged, welded or threaded-end fittings.

- They can be used with nearly all liquids, as well as those containing extreme solids content.

- Venturi tubes involve no projections into the fluid and no sharp corners. Also there are no rapid changes in contour.

Disadvantages of Venturi meter:

- Highly expensive

- Occupies considerable space

- Cannot be altered for measuring pressure beyond a maximum velocity.

Also Read:

Design of Centrifugal Pump

Valve & Its Types

Cavitation

Piping and Instrumentation Diagram – P&ID

Refrences :

Flowmax Engineering , Wikipedia, Thermopedia, Omega Engineering, NPTEL, Quora, lmnoeng,

PDF .. thanx