What is a Thermowell? Types of Thermowell

Thermowell

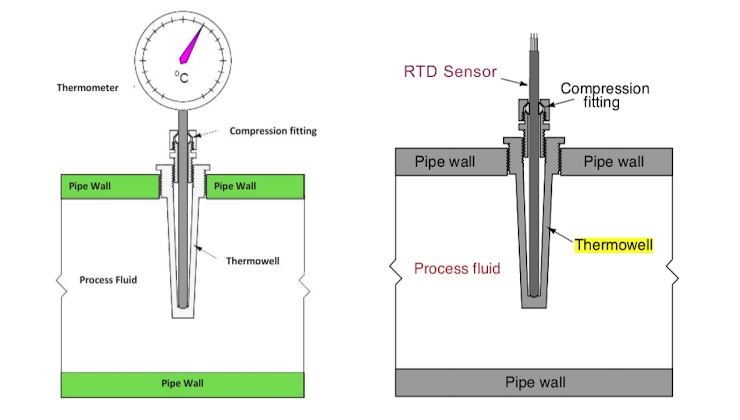

Thermowell is a cylindrical fitting and close end re-entrant (angle pointing towards inward) tube like structure, pressure tight device inserted in a process vessel / pipe. Thermowells are used to protect temperature sensors like thermocouples or RTD (Resistance Temperature Detector), temperature recorders, temperature controllers, thermistors and bimetal thermometers from flow, high pressure, material velocity, corrosion and other harmful environments which can damage those sensors.

Aricle written By : Pallavi Wankhede

Thermowell Connection in a Process:

- Thermowell is inserted and connected into a process with compression fitting. In figure 1, a thermowell is mounted through a process vessel or pipe wall.

- The pipe wall is extended into the process fluid at the desirable temperature measurement point.

- Once the thermowell is inserted through process fluid properly, the sensor is inserted into the thermowell from outside. So that whenever there is a need to operate sensor, it doesn’t need to be shutdown. It can be operated from outside as well.

- On the other hand, the thermowell is exposed to the process fluid. This allows heat transfer through its wall and also conducts the heat to the sheath and sensor as well.

- Once the equilibrium reached through sensor and sheath of thermowell, the sensor will start to provide a temperature reading of the process fluid.

- If the process fluid temperature changes, the new temperature must be taken through all those layers. It might take few seconds or several minutes depending on the process fluid application.

- In some process application, there is a sudden step change in temperature. Thus, thermowell is most applicable and important device in such real-world industrial applications.

Types of Thermowell:

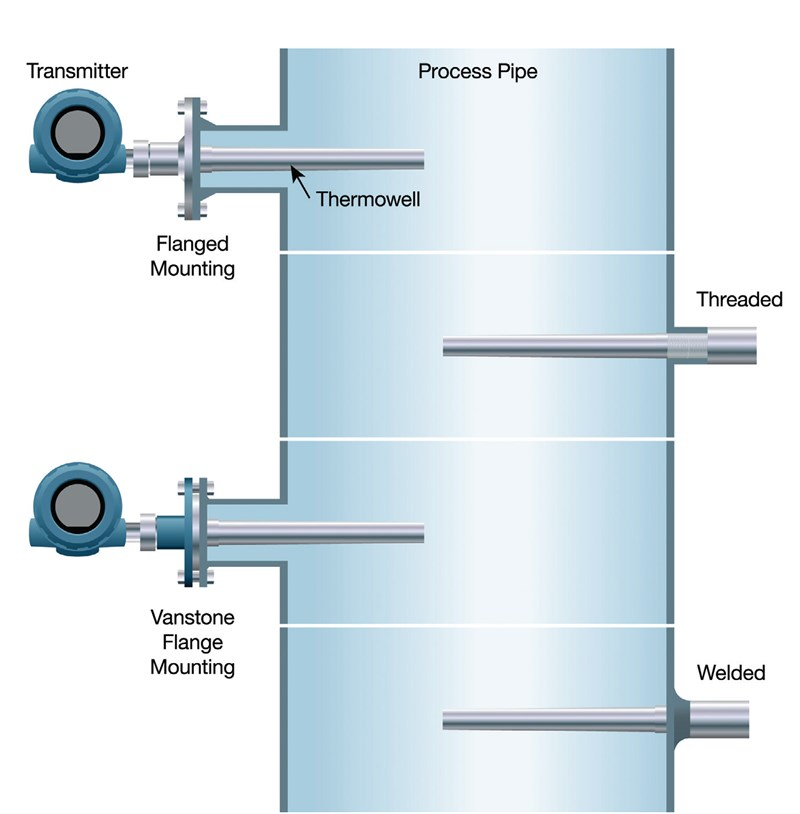

Thermowell is typically constructed from solid drilled-out bar. Thermowell is classified according to the design of stem and connection to a process. The most common types of thermowell are threaded, socket weld, weld-in, flanged, O-ring, Van stone or lap joint and there are more depending upon the requirement in process fluid and processing conditions. Some of them are listed below:

-

Threaded Thermowell:

This type of thermowell is threaded into the process vessel or process piping. Threaded thermowell allows easy installation and removal when there is a requirement. Also, it is the most common method of mounting. While, it provides lowest pressure rating and these are prone to leakage due to its threaded connection.

Figure 2 : Threaded Thermowell

2. Socket Weld Thermowell :

Socket Weld Thermowell is resistant to corrosion. It is mostly used in chemical bath application. It uses colour-coded sensors for process control.

3. Weld-in Thermowell:

Weld-in thermowell is permanently welded to a process vessel or processing pipe. This type of thermowell is most commonly used in requirements like high-velocity flow, high temperature and high pressure. They are reliable and resistant to leakage. While their removal is very difficult, there might be need to cut the thermowell out of the system.

4. Flanged Thermowell:

Flanged thermowell is spud welded onto a process vessel or process piping or bolted into a malting flange. This arrangement allows the use of different material for the thermowell coming in contact with the process fluid and for the flange. This can save the material and manufacturing costs for thermowell, sensors and the process piping.

Figure 5 : Flanged Thermowell

Selection Criteria for Thermowell:

- While selecting a particular thermowell, it is needed to consider the immersion length of thermowell, pressure, temperature, potential vibration, corrosion and the material of construction.

- While vibration effects of process fluid can cause the stem failure in thermowell.

- Fluid flow is the biggest challenge for thermowell. The thermowell is usually mounted perpendicular to the flow, thus fluid hits the thermowell broadside. This will create a partial obstruction and drag on the fluid.

- While specifying the temperature reading, the sensor needs to be placed in the pipe coming out of a vessel and reading must be taken from the centre of the pipe. Thus, the thermowell insertion length needs to be the half of the diameter of the pipe.

Content Source:

https://www.omega.co.uk/; wikipedia https://www.processingmagazine.com/;

Image Source: