What is Compressor Surge ?

Compressor :

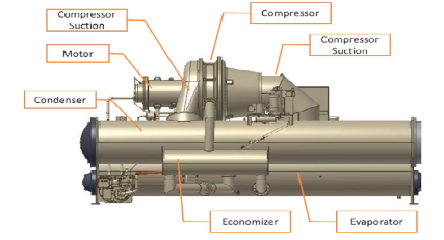

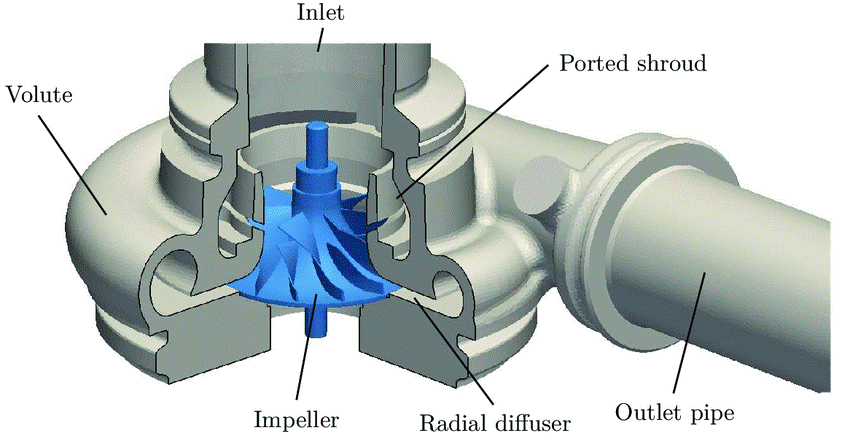

A Compressor is one of the most crucial equipment used in the production industry. Compressor and pump are similar in function. Both are used to increase the pressure of the fluid and thereby transfer the fluid through the pipe. The only difference is that type of fluids may vary. A Compressor is used for gas or air suction as gases are compressible. Also, the compressor reduces the volume of gas due to increasing its pressure while compressing the gas. Most commonly used compressors are rotary screw type, reciprocating type, axial and centrifugal. The figures shown below are of a centrifugal compressor (fig 1, 2).

Aricle written By : Pallavi Wankhede

Surge in Compressor :

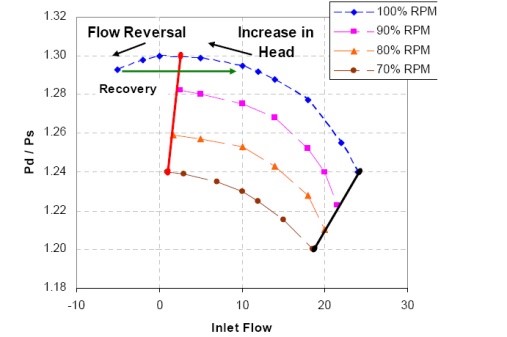

- Compressor surge is the process of formation of the reversible flow of gas through the compressor (axial or centrifugal type).

- It is a detrimental phenomenon as it will make the compressor to vibrate.

- Without a doubt, Surge might create a dead-end for natural gas compression.

- On the other, surge represents a point at which the compressor will no longer be able to supply energy to the gas to push through the compressor and further through the check valve to the discharge piping section.

- It is an unstable operating condition. Thus it is avoided.

When do we get to know about the surge?

- Surge action takes place within a fraction of seconds (150 Milliseconds). When there is a sudden fluctuation in the Ammeter, it could be assumed that surging had taken place.

- It usually happens between 50-80 % of the design flow which is also depending on the case and impellers of the compressor.

- There is a sudden drop in the gas flow as well as in discharge and suction pressure.

Read Also : Sensor and Types of Sensors

Causes of surge in the Compressor?

- Due to a sudden change in the production plant such as fire or explosion, the consumption of gas obtained from the gas receiver by the plant will stop.

- If there is any blockage in intercooler piping, the flow of gas will drop. Thus impeller won’t be able to add the pressure energy to the gas and the developed pressure due to the compressor will start to drop.

Problems that might occur after surging:

- Surging is very harmful during the working of the compressor. It can damage impellers as well as other internal parts of the compressor.

- Surge can take place in both the compressors, auxiliary and centrifugal.

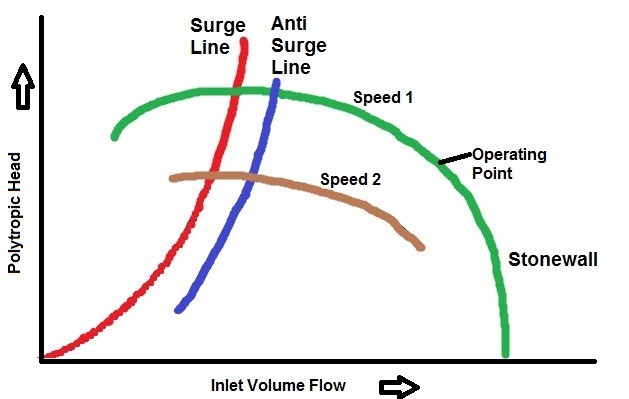

- When the developed pressure due to the compressor will drop, the compressor will reach a point where the developed pressure will be the same as the discharge pressure. At this point, the flow of the gas will stall (stop/halt), which also called “Stonewall Point”. At this point, the flow of the gas will be zero and zero pressure developed. It leads to a collapse in the compressor pressure. At this point, the pressure in the discharge piping section will be much higher than the pressure in the compressor section, which eventually leads to the surging of the gas flow in a reverse direction through the compressor.

- Due to the unstable behavior of surge, it should be avoided to prevent the damage of auxiliary equipment.

Read Also : Cooling Tower

Read Also : Three Phase Seperator

How to prevent surge in the compressor?

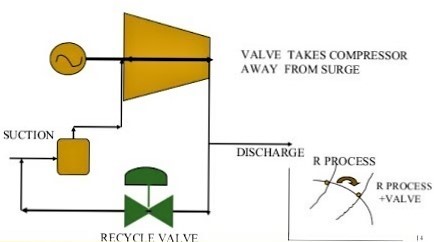

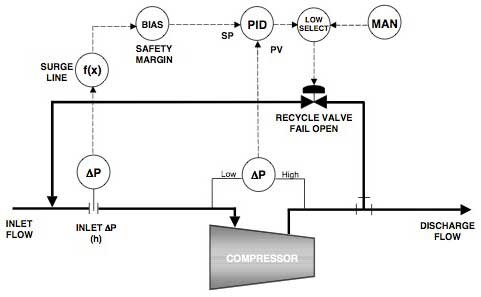

- Compressor surge is prevented with the help of Anti-surge control.

- Anti-surge control loop mainly consists of a blow-off valve (BOV), also called as stand by valve (control valve). This control valve is added between the gas receiver and compressor.

- The gas is normally flowing in the direction of suction to the compressor and the gas through the compressor directly to the receiver. This direction leads to the formation of surge. The anti-surge control valve is added at the suction to the compressor and at the receiver (discharge) entry point. Due to this valve, the reverse flow of gas from the receiver will get diverted to the anti-surge control valve (green recycle valve in fig 3) and supplied to the suction chamber. In other words, the returned gas from the receiver gets recycled and reused in the suction chamber and the process continues without any interruption.

- This helps to avoid the flow stalls condition in the compressor.

Figure 5 : Characteristic Curve for Centrifugal Curve

Content Source :

https://nptel.ac.in/ ; https://en.wikipedia.org/ ; https://www.petroskills.com/ ;

Image Source :

https://www.cbmconnect.com/ ; http://chemicalengineeringsite.in/ ; https://pgjonline.com/ ;

Content source: transvac; DAS Services; shailvac; koerting

Image Source: koerting; ironpump; ipieca

Video Source: Croll Reynolds