Distributed Control Systems (DCS) Information

Distributed control systems (DCS) use decentralized elements or subsystems to control distributed processes or manufacturing systems. They offer flexibility, extended equipment life, simplicity of new equipment integration, and centralized maintenance when used in an industrial environment.

Characteristics and Design

A distributed control system involves the placement of multiple controllers within a plant or manufacturing process. The controllers are networked to a central console. DCSs aim to centralize plant operations to allow control, monitoring, and reporting of individual components and processes at a single location.

Components

DCSs are by definition hierarchical systems, although not all systems share an identical hierarchy.

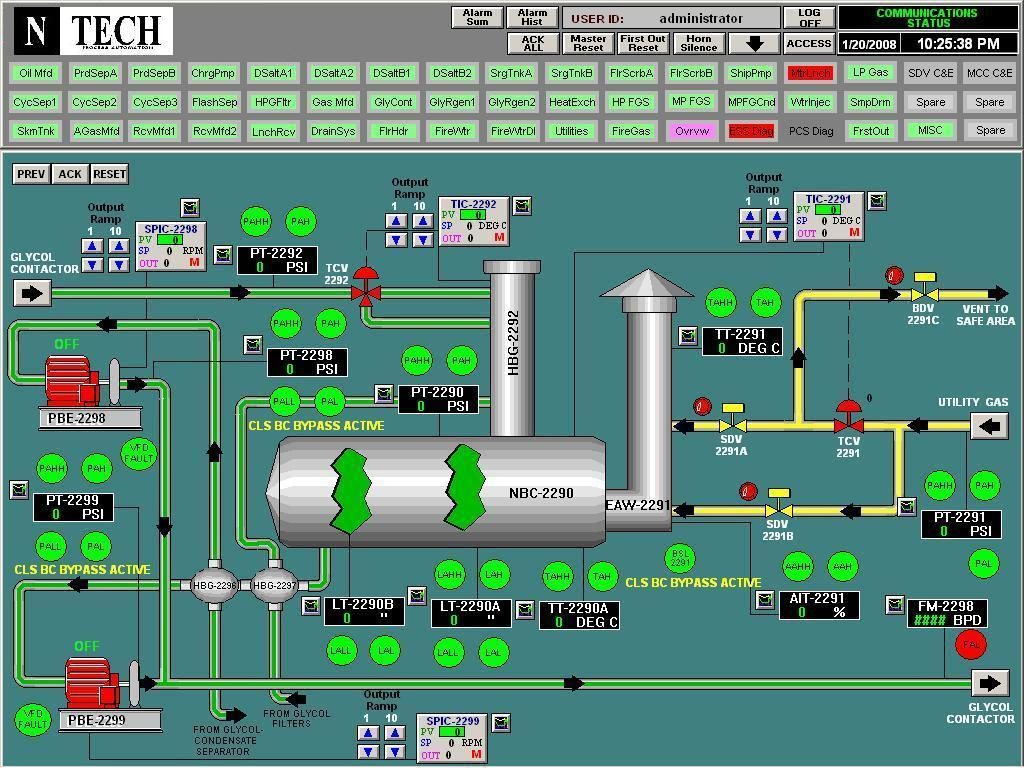

The image below shows a typical DCS. Individual controllers, supervised by master controllers, make up the lowest “field” or “plant” level of the hierarchy. The master controllers connect to individual computers and servers, which are further connected to video output devices and a human machine interface (HMI), which is the actual point of user control. DCSs are usually networked using standard protocols such as PROFIBUS and Ethernet, the latter of which is used in this particular system.

Image credit: Alstom

It is important to note that many DCS components can also operate as standalone devices. While a DCS ultimately governs the functionality of its networked components, the same components can often be reprogrammed for use in other applications.

The architecture of DCS:

Distribution Control Systems (DCS) consists of three major qualities.

1) Various control functions can be distributed into small sets of subsystems that are of semiautonomous. These are interconnected by a high-speed communication bus and their functions include data presentation, data acquisition, process control, process supervision, reporting information, storing and retrieval of information.

2) The second characteristic is the automation of manufacturing process by integrating advanced control strategies.

3) The third characteristic is arranging the things as a system.

The organizing of the entire control structure as a single automation system can be done with DCS as it unites sub-systems through a proper command structure and information flow. DCS is included with basic elements such as engineering workstation, operating station or HMI, process control unit, smart devices, and communication system.

Features:

Distribution Control Systems (DCS) can be used in various control applications with more number of I/O’s with dedicated controllers. These systems are used in manufacturing processes where designing of multiple products in multiple procedures such a batch process control.

Features of DCS are:

• System redundancy

• More sophisticated HMI

• Scalable platform

• System security

Applications:

Distributed control systems (DCS) are majorly used in manufacturing processes that are continuous or batch-oriented.

Applications of DCS include:

• Chemical plants

• Petrochemical (oil) and refineries

• Pulp and Paper Mills

• Boiler controls and power plant systems

• Nuclear power plants

• Environmental control systems

• Water management systems

• Water treatment plants

• Sewage treatment plants

• Food and food processing

• Agrochemical and fertilizer

• Metal and mines

• Automobile manufacturing

• Metallurgical process plants

• Pharmaceutical manufacturing

• Sugar refining plants

• Agriculture Applications

Benefits of using DCS include:

• It requires minimal troubleshooting

• It contains HMI graphics and faceplates

• Alarms

• Lends itself to better organization and consistency than a PLC/HMI combo

• Batch management is possible

• OPC server

• Reduced engineering time

• Redundant operator system servers

Redundancy

Most distributed control systems are designed with redundant elements. Redundant engineering increases a system’s reliability by using backup processors in case of primary processor failure. Redundant elements are necessary in DCSs because for two main reasons:

- Many DCSs control safety-critical processes in which failure or outage of equipment could cause personal injury or loss of life. A petroleum refinery is a good example of safety-critical plant. In such an environment, a control system governs flares that constantly burn gas. If the control system fails and the flares cease burning, gas collects and pools, causing an extremely dangerous situation.

- Redundancy increases equipment reliability, leaving the DCS operator to concentrate on displays, software, and applications. Because DCS systems require near-constant operator interaction at the HMI, redundancy is crucial.

Applications

Distributed control systems are most frequently used in batch-oriented or continuous process operations, such as oil refining, power generation, petrochemical manufacturing, papermaking, food and beverage manufacturing, pharmaceutical production, and cement processing. DCSs may control any of a number of different equipment types, including:

- Variable speed drives

- Quality control systems

- Motor control centers (MCC)

- Kilns

- Manufacturing equipment

- Mining equipment

Relationship with PLCs and SCADA

DCS vs. PLC

Read Also

Programmable Logic Controller

DCSs and programmable logic controllers (PLC) were historically used in dissimilar applications, but this distinction has blurred more recently. In fact, PLC and DCS architectures are often difficult to distinguish and use many of the same components, including field sensors, I/O modules, HMIs, and supervisory control systems. Distributed control systems are typically much more expensive and control continuous processes and critical applications, while PLCs are used for high-speed machine control.

The table below describes some differences between and advantages of using a DCS and PLC.

|

Type |

Product |

Value |

Control center |

Operator |

System |

Customization |

Engineering |

|

Manufacturing of specific items; simple batch control |

Low component value; easy restart after outage; downtime does not damage process equipment |

Controller is heart of system |

Operator intervenes primarily to handle errors |

Fast logic (~10 ms); no redundancy required; alarm sounds upon error detection |

Completely customizable; customization typically required |

Bottom-up design; flexible; generic solution | |

|

DCS |

Transformation of raw materials; complex batch control |

High batch value; downtime can damage equipment; difficult restart after outage |

HMI is heart of system |

Operator interaction is continuous; failure of HMI can result in outage |

Slower loop control (~100-500 ms); redundancy often required; alarm sounds prior to error |

Customized using functional blocks; algorithms may not vary with different applications |

Top-down design; functional “out of the box”; pre-defined functions specific to application |

DCS vs. SCADA

Read Also :

What is SCADA ? How does SCADA Works?

The relationship between DCSs and supervisory control and data acquisition (SCADA) is similar to that of DCSs and PLCs. In the past the two systems were used for disparate applications, but more recently their implementations and characteristics have appeared increasingly similar.

Important differences between DCS and SCADA are:

- DCS is process-oriented; SCADA is data-gathering-oriented

- SCADA maintains speed by storing good values and data for use during outages; DCS relies on constant stream of data for control

- DCS uses closed-loop control; SCADA uses human supervisory control

The image below shows the implementation of a DCS and SCADA system to integrate two automation systems. This setup is common in applications which require simultaneous process and power automation.

Image credit: ABB / Process Automation Insights

Standards

Distributed control systems may be designed and used with the aid of published standards and specifications. Some example DCS standards are:

IEC—Distributed control and filtering for industrial systems (handbook)

SAE AS5370—Fiber optic data bus for distributed aircraft control systems

References

Dresser-Rand — The case for DCS in turbomachinery

Siemens — DCS or PLC? (pdf)

Synergist — DCS vs. SCADA systems

Article Source