What is priming of a pump & Why it is important ?

Whenever the word priming comes, Undoubtedly the picture of centrifugal pump come across.

Priming a pump is probably the first and one of the most important thing we should have to do before operating the centrifugal pump.

It has been found that 80-90 % of the pump gets damaged, just not by doing the proper priming of the pump.

So first see, in a pump – what priming means.

Also Read about : Design of A Centrifugal Pump

- Priming is the process in which the impeller of a centrifugal pump is fully sub-merged into the liquid without any air trap inside.

Lets see more about priming through below mentioned Slides :

[smartslider3 slider=11]

This is especially required when there is a first start up. It is always advisable to start the pump only after priming.

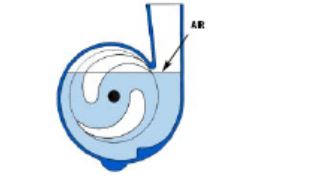

(a) Pump is Completely Primed

(b) Air is trapped inside casing

(b) Air is trapped inside casing

In figure (a) Pump is full with water and in figure (b) pump is not completely filled, will look like mentioned in above pictures.’

Standard (non-self-priming) centrifugal pumps come in many types. When they operate on flooded suction lines or in submersible applications, the impeller is surrounded by enough water to create the pressure differential and thus to pump water.

Air is the main enemy of a standard (non-self-priming) centrifugal pump. When air is trapped inside the standard centrifugal pump , it can become air-bound. It’s much harder to pump air than to pump water, so when the air “binds” the pump, the pump can no longer force the water out.

As you all know i.e P= ρ*g*h ( P= pressure buildup )

- Since the density of fluid (say water here ) is very high comprative to that of air.

- So pressure build up will be very low ..if air is present inside the casing.

- Results there may be cavitation in the pump

Also Read about : Valves & Its Types

Most of the centrifugal pumps are not self – priming.

Following steps are to be followed for priming the pump:

- Open the suction valve slowly

- Now Open the air vents on the suction and discharge piping until the pumped fluid flows out.

- Close the air vents.

- Many where foot valves are frequently used in order to keep the pump primed.

ImageSource : Waterhelp.org; Pumpstoreusa.com

Also Read:

What is Pump Head and Shut-off Head ?

Difference between Vertical and Horizontal shell and tube Heat Exchanger.

Piping and Instrumentation Diagram – P&ID

How to choose betwwen PLC and DCS systems for process industries ?

Cement Manufacturing Process

Vinyl Chloride from Ethylene

Cooling Tower

Psychrometric Chart

What is Boiler ?

Venturi Flow Meter

Pitot Tube

Coriolis Mass Flow Meter

RECIPROCATING PUMP

Design of Centrifugal Pump

Valve & Its Types

Cavitation

P&ID Symbols and Notation

What is the Difference Between HMI and SCADA?

What is SCADA ? How does SCADA Works?

What is Programmable Logic Controller / PLC ?

It is very informative and the way of explanation is good.

Hope you will post some More topics.

I ask what’s the damages if the pump start without priming

Good and enough about priming of pump